Since Leica launched the RTC360 scanner in 2018, it has been a lot of excitement around this unit, and rightfully so. It is faster than anything in its class, it is lightweight, and it comes with the VIS technology that helps pre-register the scans in the field.

It sounded like a dream machine, so the RCMonkeys team decided to put it to the test. Thanks to our friends at Transit & Level Clinic, who supplied us with the equipment, we had the chance to capture and register 4 projects. The projects ranged from 150 scans to 1000 scans. Now that we have got a taste of how it is to use this scanner, we would like to share our experience with you.

Positives

Speed = increased productivity

The RTC360 is the fastest scanner that we worked with in terms of scanning time. Compared with its bigger brothers, ScanStation P40 and P50, the acquisition time was cut in half. You may think that 30 seconds improvement for the 12 mm resolution or 60 seconds improvement for the 6 mm resolution is not that big of a deal. However, when you must capture hundreds or even thousands of scans every minute counts.

Lightweight

The weight and the size of the RTC is phenomenal. The total weight including the tripod is only 17.45 lbs.

Using lighter scanner means you can transport it easier when travel by ground or air. You can even carry it as a carry-on luggage. Also, shipping costs are significantly less, especially when you have to ship the equipment using an over-night service.

All of these considerations are great, but the biggest benefit, in my opinion, is the ease with which you can maneuver the unit in the field. Hence, you can work more hours, if needed, without putting a lot of stress on your body.

One disadvantage of using a light-weight setup is the lack of stability in windy conditions. If you often work in those types of conditions, we recommend using a heavy-duty tripod for added stability.

VIS Technology

The Visual Inertial System for real-time registration is a brilliant feature that can save you a lot of time in the office. The scanner is using internal sensors and all its cameras to track movement of the unit relative to the previous scan position. When paired with the Register360 Field app you can set a minimum number of cloud-to-cloud constraints in the field and then optimize the registration in the office.

Does it work all the time?

It all depends on the field conditions and the operator. Lighting conditions, layout, overlap between scans, and smooth and continuous movement from one station to the next, play a role in how well the system performs.

In our case, it worked perfectly 80-90% of the time. When it failed to locate its position correctly, we used the Register360 Field app to manually align the scan and optimize it to the rest of the bundle. It only took an additional minute. Hence, it is not a huge impediment.

Overall, I believe the VIS of the RTC360 is one of the best in the industry and I hope it will become the standard for the new scanners.

Simple UI

The touch-screen control of the RTC360 does not give you much control over its settings. However, for a beginner this scanner is perfect.

The UI feels very modern and seems that it was designed for speed and ease of use. The only things that you can adjust are your scanning settings: resolution, colors, activation of the VIS, and the choice to perform a double pass scan to remove moving subjects.

However, for more experienced users I wish there was an advanced mode. While in the field, I often found myself in situations when I needed to capture a limited view range at a high resolution.

Extremely clean data

The RTC360 does not disappoint when it comes to data accuracy and noise reduction. When I first tested the unit in 2018, I did a side by side comparison with a ScanStation P20. We overlapped scans captured with the two units and I was not able to find any visible differences up to 50 m (164ft). Even past the 50 m range, the difference was barely noticeable.

The RTC360 is suited for most interior applications and some exterior jobs. If you need to capture projects that require high accuracy at distances greater than 50m, then I recommend using the ScanStation P40, the ScanStation P50, or the Z+F Imager 5016.

Beautiful color capture with the on-board cameras

We have always struggled to get accurate colorization of the scans using the internal cameras of the Leica scanners. If we wanted good colors, we needed to use an external camera kit. It is slow and it disrupts the scanning flow.

Z+F Imager 5016 has been probably the best scanner in the industry that is able to deliver great color scans right out of the machine. However, with the introduction of the RTC360 things have changed. Equipped with 3 cameras the scanner captures beautiful HDR photos in most light conditions. Besides the fact that the colors are accurate, the system is the fastest in the industry. It takes approximately 1 minute to capture a full spherical image. And that is a big deal.

Before the RTC360, colorizing the scans would always double or triple the time required to be in the field. I cannot even emphasize how boring it is to wait an additional 4 to 10 minutes for the photos to be captured.

If your projects require you to capture excellent color scans, the RTC360 scanner should be at the top of your list.

Time savings

We have seen a huge time savings by using the RTC360 compared with using any P Series scanner.

Setup time: up to 1 minute

Scanning time: up to 1 minute and 30 seconds

Registration time: up to 2 minutes over using Visual Alignment

Our scanning crew is averaging between 20 and 25 scans per hour using a heavy-duty setup, scanning at Medium Resolution (6mm@10m). With a P Series scanner, we are averaging between 10 and 15 scans per hour. If the field conditions permit, you can use a tripod dolly to further increase productivity.

Data organization

How many times have you received raw data from your field crew or a 3rd party company without any field notes? On top of that, all the scans were named Station001 to Stationxxx? We all know that trying to register a project that you did not physically visit makes the process slightly more difficult.

Having a standard naming convention for your scan stations and an App like Register360 Field to help you organize, name, and rename your scans in the field makes a huge difference for the person that registers the data in the office.

Also, if you need to add more scans for a particular project area, you can easily append the new scans to the appropriate project and bundle.

We usually like to organize our scan stations in bundles up to 50 scans and be very specific with the names. For example, our standard naming conversion is BuildingName-Level-Area/Wing/Suite-StationNumber.

Negatives

Lack of dual-axis compensator

This can be a deal breaker for a lot of people. The tilt accuracy of 3’ offered by the IMU is not enough for most engineering or architectural applications.

On our first project we solely relied on the IMU to get leveled data. While registering the scans we realized we made a huge mistake. We were dealing with a stadium project and the slightest tilt was amplified at hundreds of feet away from the scanner location. To deliver a good final product our team had to manually register a lot of the scans using the three-pick method, as well as adjust the coordinate system to get a “leveled” point cloud.

From a productivity standpoint this project was a failure. All the time saved in the field was spent in the office.

We have learned from our mistakes and we adjusted our field workflow to ensure we always get leveled data.

Due to the lack of a dual-axis compensator there are two challenges that you will have to overcome:

Sometimes the IMU does a bad job correcting the scans for a proper pre-registration in the field. The automated workflow becomes not so automated when you have to manually move and rotate each scan to ensure a good alignment to the previous station. It can affect the scanning pace tremendously.

If for some reason you have to optimize a constraint between two scans, when one of them is tilted and you are using Cyclone 9.3.2 or older, the visual alignment method might not work. You will have to rely on picking three coincidental points between the two scans. We all know that this workflow is time consuming.

Lack of leveling capabilities

The beauty of using the RTC360 is in its speed and its light weight. Since the scanner is not equipped with a dual-axis compensator, we wanted at least to manually level the unit using a physical or a digital level. Unfortunately, the light-weight setup does not offer that capability.

The only way to level the scanner is to switch to a heavy-duty setup and use the 8’ bubble level situated on the tribrach. We discovered that using this setup gives you the best results, both in terms of speed and getting excellent data for the processing phase.

We sacrificed some maneuverability in exchange for data that is closer to being leveled. As a matter of fact, since we switched to the heavy-duty setup, we have not had any tilted scans that had to be corrected in the office.

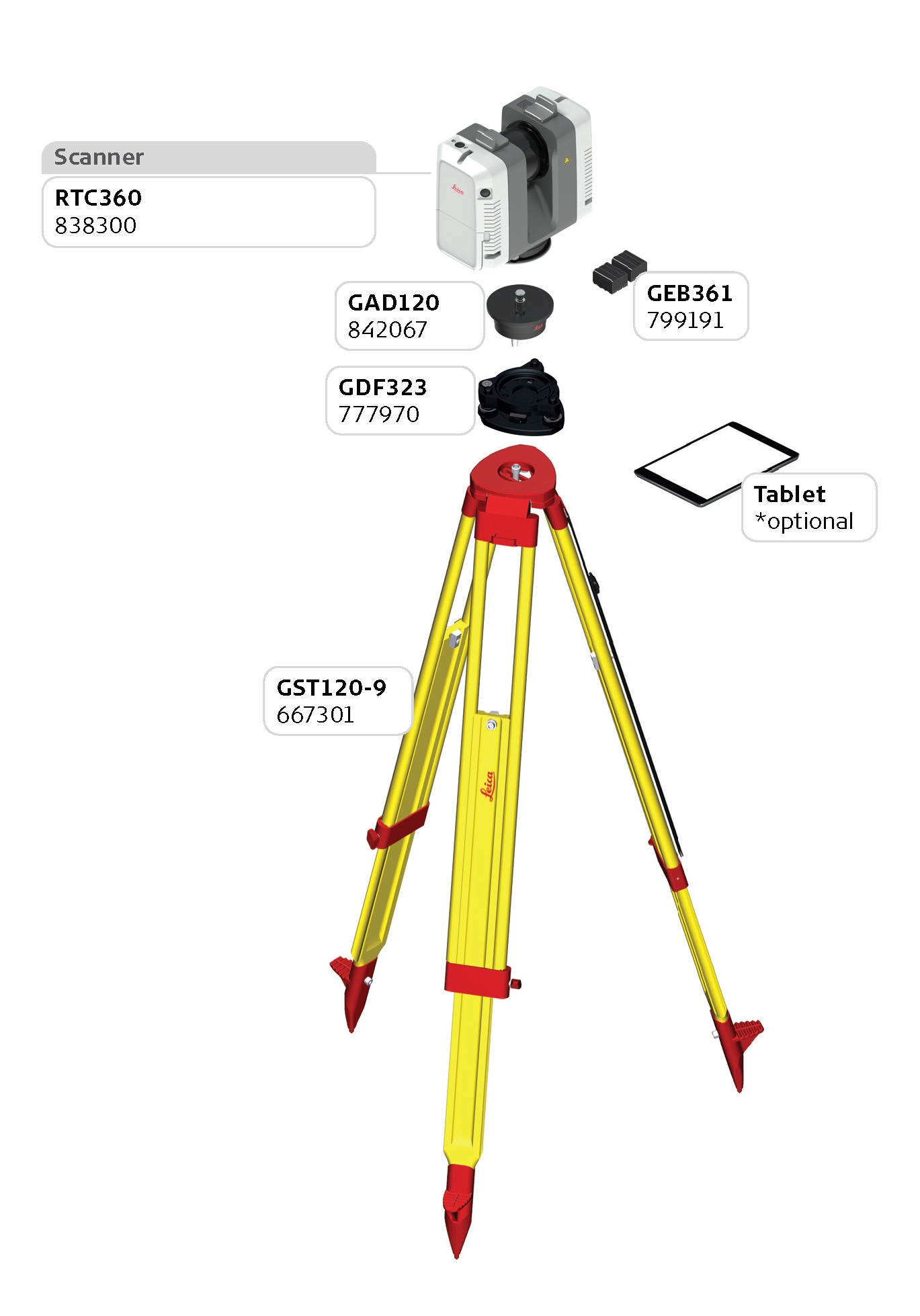

RTC360 - RCM’s preferred setup

File sizes

When I initially demoed the unit in 2018, I was extremely surprised by how large the binary files that came from the scanner were.

For one medium resolution scan (6mm@10m) the file size was 1 Gb. If I included the HDR photos I was up to 2.5 GB per scan. This was way too big of a file compared to what I was used to. It was 4 times larger than what I was getting from a P series scanner.

Then I imported the raw scans into Cyclone and registered them to determine if the data size will be shrunk to what I am used to seeing: approximately 6MB/1 Million points. Unfortunately, that was not the case. The Cyclone DB was 4 times larger. So were the exports and the Recap deliverables.

This was a big issue for us. In order to work with RTC360 data we needed to dedicate 4 times more storage space to process, store, and archive our projects.

For example, in order to register a large project of 1000 scans (medium resolution) you will need at least 2TB of available space on your workstation. At the end of the project you will need to allocate approximately 2.5TB on your server to store a project of this size. Keep in mind that you will need even more space if you want to colorize the scans. That is a lot of space in my opinion.

In May of 2019, Leica released a new firmware that reduced the file sizes by about 25%. This was a great improvement. However, I would like to see them go down even more.

Gets slower with bundle size

Organizing your scans into projects and bundles is critical for a smooth registration in the office. But most importantly it is critical for maintaining the scanner operating at its maximum speed.

We have noticed that the entire system (the scanner and the Register360 Field App) becomes sluggish after you capture more than 50-75 scans per bundle. You can have more scans per bundle, but you will have to sacrifice speed.

Our preferred workflow is to start a new bundle once we reached the “maximum” number of scans, but making sure to maintain the naming convention of the scan stations. To keep your data organized, you can rename each bundle within the Register360 Field app. However, the bundle names will not be carried over into Cyclone. That should not be an issue since it will be extremely easy to identify how the bundles (or groups in Cyclone) relate to each other based on the names of the scan stations.

Scanning view range - non-customizable

There are times when you need to capture targets or objects that are situated at a considerable distance from the scanner.

If you are using any of the ScanStation units you can perform a custom view range at a high resolution and capture the desired object in a few seconds. This feature has been proven to save time and reduce the file size of the scans. However, the RTC360 does not yet offer this feature. You would have to perform a full dome high resolution scan. We hope this will change with future firmware updates.

Conclusion

The RTC360 is the fastest scanner on the market. It is easy to use, and it can cover most project needs. The VIS technology pared with the speed of the scanner allows you to capture and register two or three times more data than with any other scanner. This machine is a workhorse. However, because the scanner is lacking a dual-axis compensator you would always want to use survey control on every project to ensure the data is leveled. Another solution is to pair the RTC360 with a scanner that has a survey grade dual-axis compensator, like a ScanStation P40. For that reason, we do not believe the RTC360 can be the only LiDAR instrument in your inventory.